Partial Hand Prosthetics Company Scales Manufacturing with Help from 3D Systems

Designs is an innovator in the field of partial hand prosthetic design and provides robust artificial digit solutions through a combination of additive manufacturing (AM), mechanical design, and clinical care. Founded by researchers out of the Bio mechatronics Development Laboratory at the University of Colorado, Point Designs needed manufacturing support when demand for its products outpaced in-house capacity. By selecting 3D scanning services in India, Systems as its production partner, Point Designs solved its supply issue and advanced its product development process. Through close collaboration with 3D Systems’ experts, the company transitioned from steel to titanium in just six months, gaining workflow efficiencies and valuable knowledge to advance its portfolio.

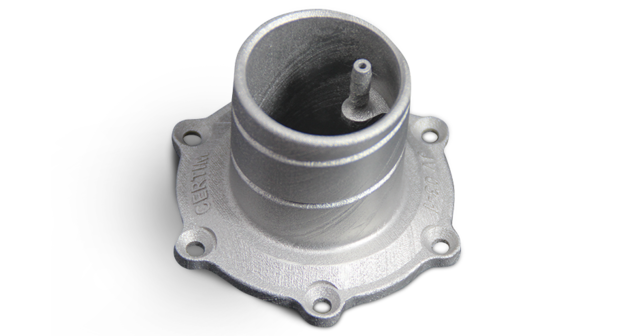

PARTNER TO SCALE AM PRODUCTION OF PARTIAL HAND

PROSTHETIC COMPONENTS

With

early access to lab resources at the University of Colorado, Point Designs

created its Point Digit solution with metal 3D printing in India

mind from the very beginning. As the solution gained popularity, however, the

company needed a partner to help grow its capacity. 3D Systems’ track record in

medical device manufacturing, expertise in high quality, repeatable titanium

printing, and intimate knowledge of AM technologies and processes guided Point

Designs’ decision. Together, the companies adapted the Point Digit solution to

titanium and fast-tracked it’s time-to-market to achieve functional, aesthetic,

and optimized product components.

Collaboration to Advance Design for Additive Manufacturing

When

Point Designs engineered its Point Digit solution, it took advantage of the

benefits of design for additive manufacturing (DfAM) by creating organic

shapes, semi-hollow structures, and assemblies in situ. These types of features

are uniquely enabled by AM and are a compelling reason for many to use the

technology, enabling parts to be designed specifically for their intended

function, at reduced weight, and with reduced assembly. However, achieving a

successful 3D print can be tricky, especially when the final product entails

detailed mechanisms which require strict tolerances.

One

key AM-enabled feature that Point Designs uses is a live hinge, which is

printed as an assembly in situ and allows rotation for more natural movement.

Sliker says the ability to print this assembly in place is an incredible

benefit because the hinge components are not only small, but they are internal

components. “To assemble them any other way would be difficult, if not

impossible,” says Sliker. “Not only would it be time-consuming, but you’d have

to keep track of some really tiny parts. Printing everything in place with a

live hinge really simplifies our assembly and manufacturing.”

Consultation for Optimized Print Strategy for Mass Production

Despite the short timeline to product launch, Point Designs had some design-related challenges to overcome when it started its work with 3D Systems service partners in India, in particular when it came to part orientation. Point Designs had selected its existing build orientation to accommodate the critical dimensions and tight tolerances of its final parts. However, this orientation was not optimized for scaled production. 3D Systems and Point Designs worked together to devise a new print strategy that would enable substantially more parts to be printed in a single build while taking downstream processes into account. To avoid support scarring on critical surfaces, the two companies worked together to come up with support structures that would be easy to remove, as well as post-processing techniques to deliver the desired finish on those surfaces.

Transition to Premium Titanium Material

When Point Designs was searching for a

manufacturing partner, its primary concern was capacity. By selecting 3D

Systems, Sliker says it gained titanium as a bonus. But Point Designs is not

the only one benefitting. Jeff Solberg is an end-user of the Point Digit

solution and has worn both the steel and titanium versions. With a 30%

reduction in weight enabled by the new material, the difference was instantly

noticeable.

Reduced Assembly

3D

Systems collaborate on four products, each comprised of multiple 3D printed

components and available in multiple sizes for a total of 17 SKUs and 107

unique components. Once Point Designs receives the printed parts from 3D

Systems, they are assembled by the Point Designs team using a combination of

off-the-shelf and customized components. Following assembly, Point Designs

delivers its products to a prosthetist, which creates a custom prosthetic

socket for each recipient.

In

terms of solving its supply issue, Griffin , business development specialist at

Point Designs, says that since working with 3D Systems, the companies have

established a reliable production cadence and Point Designs hasn't since

experienced any back-ordered products, which is a meaningful and welcomed

achievement. This has been possible through the close and open communication

between Point Designs and 3D Systems, allowing each to have visibility into the

other’s timelines for accurate forecasting and planning. Following the

successful launch of Point Digit 2.0, a Class I medical device, Point Designs

is now pursuing numerous other prosthetic offerings which will leverage 3D

Systems’ expertise.

For

more information about 3d scanners & haptics visit: https://www.mavericsolution.com/scanners.html

Comments

Post a Comment